Blindly embracing the new technologies might not be wise or provide the desired outcome

Wastewater treatment and recovery are critical to address water scarcity and environmental pollution. Indian cities currently treat only 28 per cent of the 72,368 million litres of sewage they generate every day, as per the latest data released by the Central Pollution Control Board in December 2022.

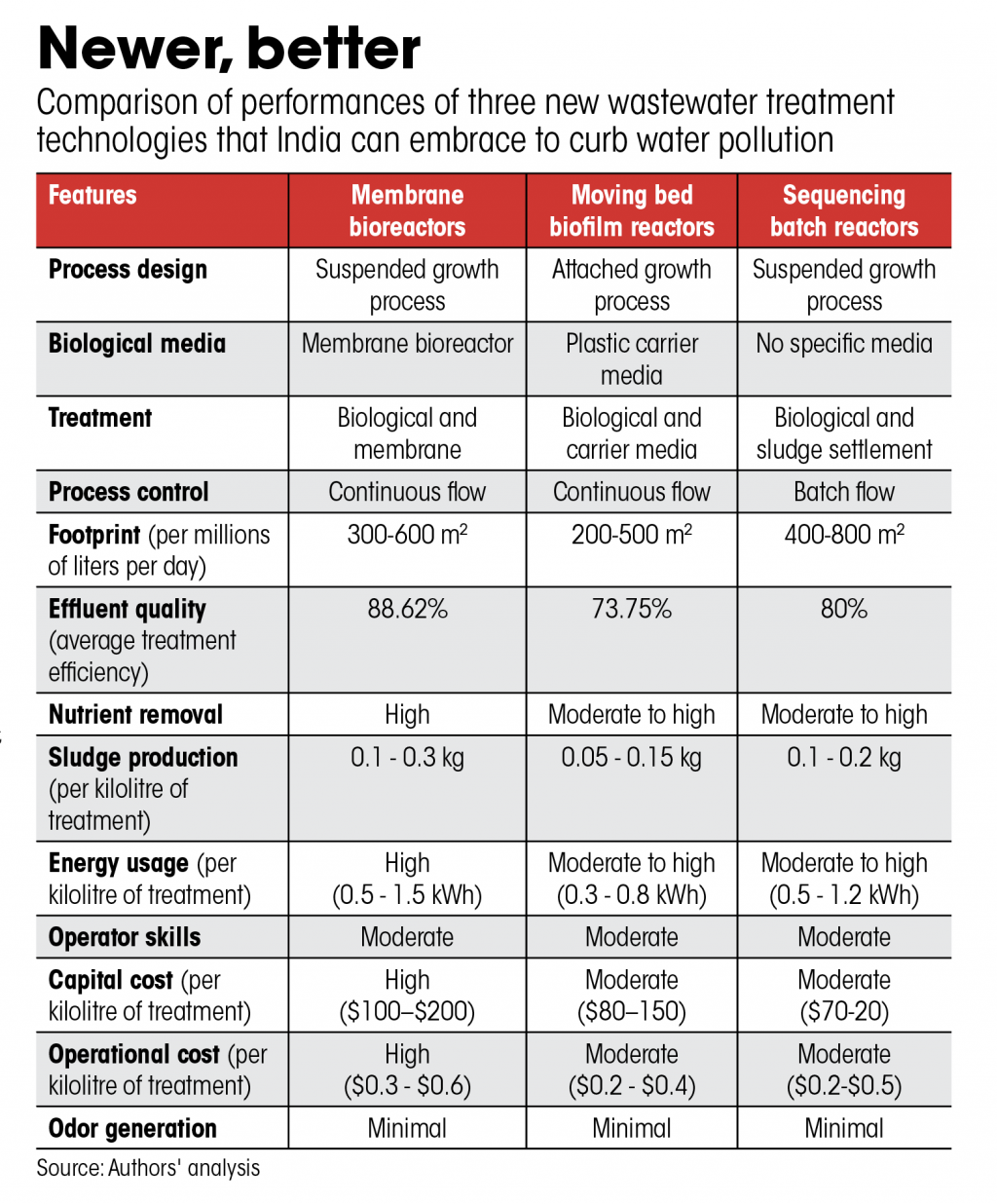

While the country clearly needs to increase its treatment capacity, it also needs to upgrade the currently employed wastewater treatment processes for more efficient technologies. Most sewage treatment plants in the country rely on outdated technologies such as the activated sludge process, planted drying beds, soil biotechnology and upflow anaerobic sludge blanket reactors that have a treatment efficiency of around 65 per cent and are cumbersome to set up and manage.

The story is slowly changing with several states in recent years opting for newer technologies that have treatment efficiency of around 80 to 90 per cent. Almost all the sewage treatment plants set up in Andhra Pradesh and Telangana after 2018 are based on two such technologies—sequencing batch reactors (sbrs) and moving bed biofilm reactors (mbbrs). Telangana’s capital Hyderabad, in a first, recently upgraded an existing sewage treatment plant that releases its effluent into the Durgam Cheruvu Lake with sbr technology. Bihar has replaced most of its obsolete and inferior sewage treatment plants with sbrs. Similar upgrades are also reported in Maharashtra, Goa, Haryana, West Bengal and Uttarakhand.

When compared to traditional treatment techniques, these technologies have higher treatment and nutrient removal capacity, are better at handling shock loads (spikes in pollution concentration in wastewater), are more resource-efficient and generate high-quality effluent with greater reuse potential.

But blindly embracing the new technologies might not be wise or provide the desired outcome. The choice between these systems depends on project-specific considerations, including effluent quality requirements, land availability, energy requirements and costs. Here is a checklist that will help administrators, companies and townships identify the technology ideal for their needs.

Efficient but costly

Membrane bioreactor or mbr is a wastewater treatment with the highest rate of filtration that is achieved by combining biological processes with a membrane. Sewage is first treated inside a bioreactor where microorganisms break down organic matter and eliminate pollutants by converting them into carbon dioxide, water and biomass. After this, the wastewater is pressured through a fine-pore membrane to segregate treated effluent from micro-organisms and suspended solids, and ensure the production of high-quality, clarified effluent that can be reused without further treatment. It also has a small footprint, making it ideal for areas with land scarcity. Finally, it offers a high level of automation and process control through sensors for real-time control over filtration.

While highly efficient, the technology is energy-intensive and expensive to set up and operate. It also requires regular maintenance, skilled human intervention and frequent system downtime to replace the membrane.

Owing to the high maintenance and operation, adaptability is limited for mbr. Most government-owned sewage treatment plants follow a dilution approach where the treated effluent is released in waterbodies or disposed of through sewage farming and, hence, do not require high filtration levels.

The technology, however, is imperative for food processing and similar industries, which as per the current rules, need to achieve zero-liquid discharge. This means reusing the wastewater internally.

Versatile option

Extensively used for handling municipal sewage, moving bed biofilm reactor or mbbr is a type of wastewater treatment process that takes place in a bioreactor with plastic carriers on which microorganisms can attach and thrive. As wastewater flows through the bioreactor, the microorganisms in the biofilm metabolise organic matter and pollutants in the sewage. The biofilm carrier is designed to freely float within the bioreactor, facilitating the distribution of wastewater and oxygen.

mbbr boasts of several advantages. Owing to the diverse microbial population that can thrive on the biofilm, the process has a high treatment efficiency and can handle wastewater with different pollutant compositions. The absence of a membrane indicates the bioreactor produces limited sludge, requires less energy to operate and has negligible downtime.

There are some limitations, primarily pertaining to the limited removal of solids and nutrients, as mbbr’s primary focus is on organic matter removal. Further, the biofilm carriers within mbbrs can clog up the system if not effectively managed, necessitating regular mainte-nance. It also relies less on automation and focuses on manual adjustments to control parameters like aeration and effluent quality.

Ideal for small scale

With an efficiency rate comparable to mbbrs, sequencing batch reactors or sbrs allow high automation and process control. These combine biological treatment and sedimentation within a single bioreactor and each batch cycle begins with the filling up of the reactor with wastewater. This is followed by aeration to stimulate microorganisms to metabolise organic matter. Once the biological reaction is complete, aeration is halted, allowing suspended solids to settle at the bioreactor’s bottom. This results in the formation of a supernatant layer above the settled solids, which is decanted, leaving the settled solids in the reactor. The treated effluent is typically discharged or further processed.

SBR offers several advantages in sewage treatment. Its flexible operating mode enables efficient treatment of diverse wastewater flows and compositions. The batch process allows precise control over treatment parameters and facilitates the removal of nitrogen and phosphorus through specific process stages. Moreover, sbr systems require smaller reactor volumes compared to continuous flow systems, reducing both the footprint and construction costs.

SBRs offer a flexible operation that can easily adapt to different wastewater characteristics. They are energy-efficient as they do not require membrane filtration. Additionally, sbrs have the capability to achieve enhanced nutrient removal, making them suitable for applications with strict effluent nutrient limits.

However, there are limitations to consider. sbrs have longer treatment cycles compared to continuous-flow systems, which may limit their capacity for high-flow applications. They also generate a significant amount of sludge, requiring proper management and disposal strategies. The operation and control of sbrs can also be more complex compared to mbrs and mbbrs, necessitating advanced process control systems.

Informed decision

The analysis clearly shows that while the new technologies are highly efficient, serious thought must be put into identifying the right alternative for the task. mbrs offer high-quality effluent suitable for water reuse applications but involve higher capital and operational costs due to energy requirements and membrane fouling. mbbrs, on the other hand, provide robust performance, lower energy consumption and reduced sludge production, making this a preferred choice for decentralised applications. sbrs are particularly favoured for small to medium-sized plants due to their ease of operation and cost-effectiveness. They are suited for plants with frequent start-stop operations or limited space.

Atun Roy Choudhury is head, technical at Cube Bio Energy, a waste management company in Telangana; Neha Singh is with Banka Bio Limited, a liquid waste management company in Hyderabad, Telangana; P Sankar Ganesh is with Birla Institute of Technology and Science, Pilani, Hyderabad campus; Resham Bhalla is with Loknete Vyankatrao Hiray Arts, Science and Commerce College, Nashik, Maharashtra; K Mahalakshmi is with MFive Water and Environmental Solutions, Secunderabad; and K Sandhya is with Food Corporation of India, Nalgonda, Telangana.

Views expressed are the author’s own and don’t necessarily reflect those of Down To Earth.

We are a voice to you; you have been a support to us. Together we build journalism that is independent, credible and fearless. You can further help us by making a donation. This will mean a lot for our ability to bring you news, perspectives and analysis from the ground so that we can make change together.